Most garage door failures do not start as sudden events. Many begin as small changes in alignment, friction, or lift support that build across weeks of daily cycling. Homeowners often notice louder travel, slower response, or a door that closes unevenly before a breakdown happens.

Scheduling garage door service when early changes appear supports safer operation and helps reduce repeat disruptions. Service visits focus on balance, hardware stability, and controlled travel, since those factors influence how well the door responds to safety features and how evenly the load is shared across parts. Regular attention also supports consistent closure and security, helping homeowners avoid last-minute access issues.

Minor Alignment Problems That Lead to Larger Failures Over Time

Alignment controls how rollers seat in tracks and how sections meet during travel. When tracks shift slightly, hinges loosen, or rollers develop flat spots, friction increases, and the door can start binding at the same points. Binding forces the opener to pull harder and can also stress hinges and brackets as sections twist during movement. Over time, small alignment drift can turn into wear patterns that reduce the lifespan of multiple parts.

Early alignment-related indicators include:

- The door rubs in one spot during travel

- One side appears to move slightly ahead of the other

- New rattling develops near hinges or roller brackets

- The opener pauses or reverses without a clear obstruction

- The door closes off-square and leaves a visible gap

A professional evaluation can determine whether the issue is track spacing, a worn roller, or hardware movement that requires correction. Many homeowners also schedule garage door repair when alignment drift begins, causing reversals or uneven closure.

For a safety-focused overview of long-term care, visit our blog, “Why Is Garage Door Maintenance Critical for Long-Term Safety?“

Friction and Wear Patterns That Regular Maintenance Helps Reduce

Friction is a leading cause of garage door performance problems because it accelerates wear across rollers, hinges, tracks, and opener drive components. As resistance builds, door movement often becomes louder, less consistent, and harder to control. Vibration from excess friction can also loosen fasteners over time, increasing the risk of uneven travel or sudden stops during daily operation. Regular maintenance helps identify friction points early, allowing adjustments before wear spreads through the system.

Maintenance often helps reduce failures tied to:

- Roller wear that increases resistance and track stress

- Loose hinges that change section spacing

- Track mounting movement that creates rubbing points

- Seal drag that affects closure and travel consistency

- Opener strain that reduces reversal reliability

In many cases, professional garage door lubrication services are recommended based on door design and operating conditions, since reduced friction supports smoother travel and lowers strain. When friction is left unaddressed, wear patterns can compound and raise the likelihood of alignment problems, including conditions that may lead to an off-track garage door event.

To understand how skipped maintenance can affect garage door springs and create safety risks, check our article, “What Happens When Garage Door Maintenance Is Skipped?”

Lift Support Changes That Can Trigger Sudden Breakdowns

Lift support depends on stable tension and even load sharing across springs and cables. When lift support drifts, doors can become heavier, close harder, or move unevenly. Those changes can lead to sudden malfunctions, especially when a door is used frequently. A door that becomes difficult to control can also increase strain on the opener and create safety concerns.

Lift-support warning signs include:

- The door feels heavier during manual operation

- The door will not stay in place when partially open

- The door closes faster near the floor

- The opener struggles or produces a strained sound

- Uneven travel suggests an imbalance across lift points

A technician may check spring support and cable seating, since a worn garage door cable can create uneven lift and increase stress on other parts. When failure risk increases, the door may create conditions that lead to garage door emergencies, such as a door that fails to close securely.

For guidance on professional timing, visit our blog, “When Does Garage Door Maintenance Need Professional Attention?“

What are Preventive Service Visit Reviews to Stop Failures Early

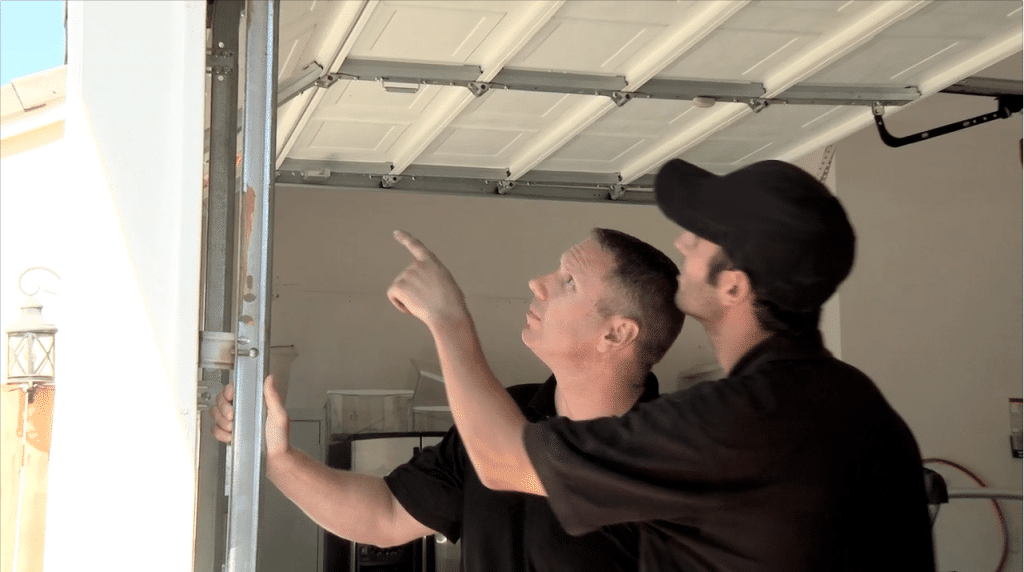

Preventive visits focus on identifying wear patterns before they become failures. Professionals evaluate the door as a connected system, since a change in one area often affects other parts. The goal is improving predictability, safety, and daily reliability.

Door balance and controlled travel

Technicians evaluate balance and how the door behaves through travel. Stable balance helps reduce operator strain and supports safer operation.

Hardware stability and wear patterns

Hinges, rollers, and brackets are checked for looseness and wear. Hardware stability helps reduce vibration and friction.

Opener interaction and safety response

Professionals review how garage door openers respond under load, including reversal behavior and limit accuracy. Safe interaction depends on controlled resistance.

Section condition and stress points

Panels, seams, and reinforcement points are inspected to confirm stability. A weakened garage door panel can increase misalignment and stress across hinges.

A preventive evaluation supports decisions to reduce the risk of repeat breakdowns.

Maintenance Planning That Supports Reliability Across the Entire System

Maintenance planning is most effective when grounded in real-use patterns and door design. High-use households cycle the door more often, which increases wear on rollers, hinges, and opener drive parts. Weather exposure can also affect seals, corrosion risk, and performance at the bottom section.

Routine service structure

Homeowners often schedule routine garage door maintenance to keep wear patterns from becoming failures. Structured planning supports more predictable daily operations.

Inspections and adjustments for stability

A garage door inspection can identify early drift in alignment, lift support, and hardware security. When needed, a garage door tune-up can restore smoother travel.

Planning upgrades when needed

If long-term stability is difficult to maintain due to age or recurring issues, homeowners may consider replacing the garage door. Others explore custom garage doors to better match insulation goals or daily use needs.

Planning supports fewer disruptions and helps homeowners make decisions with better timing.

A Maintenance Checklist Homeowners Can Use to Understand Professional Work

A clear checklist helps homeowners understand what professionals evaluate and why those checks reduce failure risk. A structured garage door maintenance checklist approach supports consistent review across key safety and reliability points.

Common checklist topics include:

- Track alignment and mounting stability

- Roller condition and smooth travel

- Hinge and bracket fastener security

- Cable seating and even pull

- Spring support indicators and balance behavior

- Opener limits and reversal response

- Seal condition and closure consistency

Many homeowners search for garage door maintenance near me after noticing noise or uneven closure because a checklist-based review helps identify what is changing and why.

Build More Reliable Operations With Consistent Professional Care

Regular maintenance prevents failures by reducing friction, correcting alignment drift, and confirming that lift support remains stable. Professional reviews also help confirm the opener’s safety response and identify wear patterns before they lead to a sudden malfunction. When homeowners address early signs, they often avoid unpredictable access issues and protect the load-bearing components through every cycle.

MF Solutions Inc helps homeowners support more reliable garage door operation through consistent professional care focused on reducing friction, correcting alignment drift, and confirming stable lift support. Our technicians verify opener safety response and track wear patterns early to minimize the risk of sudden malfunction and protect load-bearing parts throughout every cycle.

Contact us today or call now to schedule a maintenance review to ensure smoother operation and more reliable daily access.

Frequently Asked Questions

Why do failures often follow weeks of small changes?

Wear patterns usually build over time as friction rises and alignment drifts. Professional inspection helps identify those early changes before a breakdown occurs.

Can maintenance prevent an off-track event?

Maintenance can reduce risk by supporting proper alignment and smooth roller travel. A professional can confirm track stability and consistent travel behavior.

Do openers cause failures or respond to door resistance?

Openers primarily respond to resistance rather than cause failure. Rising friction and imbalance increase strain and may alter reversal behavior, which is why door condition must be evaluated alongside the opener. Wikipedia notes that garage door openers are designed to react to resistance, not compensate for worn or unbalanced doors.

What makes a preventive approach more effective than reactive repairs?

Preventive care identifies wear patterns early, enabling safe service scheduling. Reactive repairs often occur after disruption and may involve additional strain across multiple components.

When should service be scheduled?

Service is recommended when door travel becomes louder, uneven, or less predictable, or when gaps and repeated reversals begin appearing. For context on what professional service may involve at later stages, a step-by-step guide from This Old House outlines the key phases of garage door replacement, from removal through final safety checks, helping homeowners understand when routine service may no longer be enough.

How does continued use worsen developing issues?

Continued cycling increases stress on already-worn components. Small alignment or balance issues can escalate into larger mechanical failures if left uncorrected.

Why do minor noises matter during operation?

New or changing noises often indicate rising friction or shifting components. These sounds usually appear before visible damage or performance loss.

Can environmental factors accelerate failure timelines?

Yes, temperature changes, moisture, and debris can increase wear and corrosion. Environmental exposure often shortens the time between early symptoms and complete failure.

Does an inconsistent door speed signal a developing problem?

Yes, changes in speed often indicate imbalance or resistance within the system. Inconsistent movement is an early warning sign that should not be ignored.

Why is early evaluation safer than waiting for failure?

Early evaluation reduces the risk of sudden loss of control or access. Addressing issues before failure supports safer operation and more controlled repair planning.